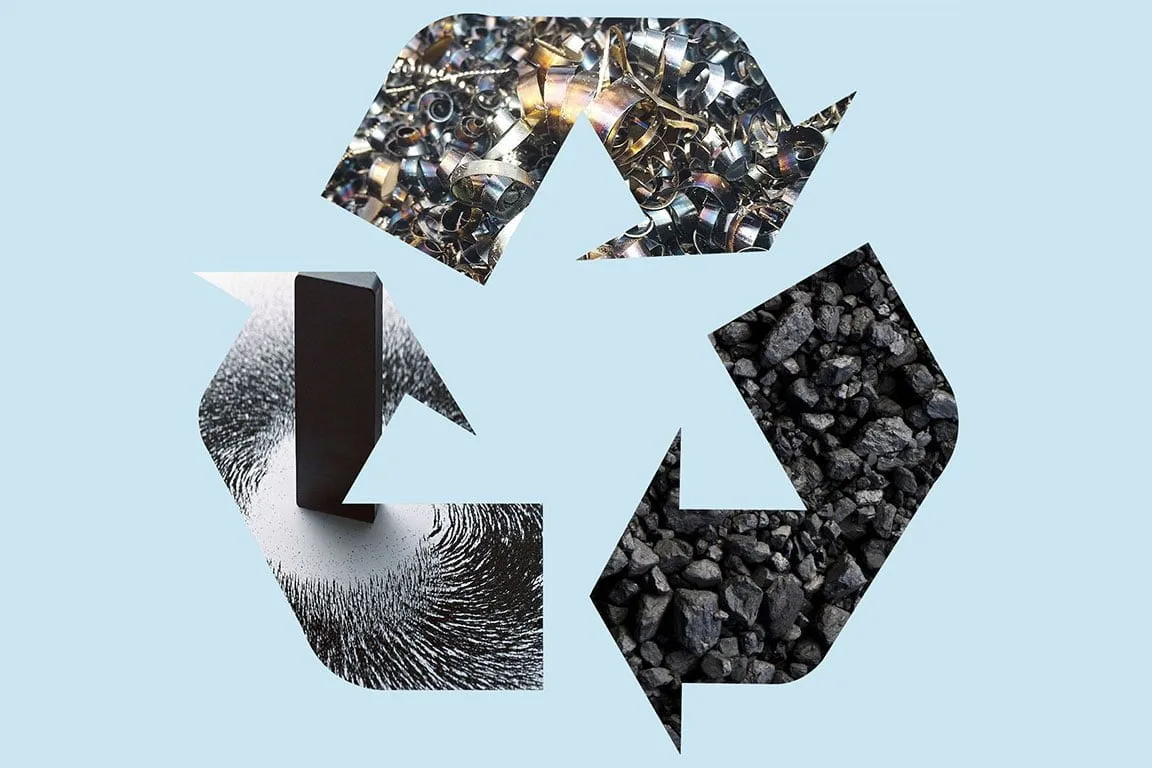

The industry uses Magnetite to produce dense medium separation slurry for coal washing, mineral processing and recycling of metals and plastics.

Heavy media gravity separation means separating products with different densities. Both Magnetite and water are used to make a slurry on which one product will float (the product with a lower density than the slurry) and in which the other product will sink (the product with a higher density than the slurry). Hence our customers often use the term sink-and-float separation. Depending on the densities of the products that need separating, you can vary the ratio of magnetite and water in the slurry to achieve the required intermediate density.

For many heavy media separation processes, the right slurry density can be reached with Magnetite. The particle density of our Magnetite is 5.1 t/m3.

Your benefits when using LKAB Minerals’ Magnetite for media separation:

Because we get Magnetite from our own resources in the northern part of Sweden, we know that the properties of our products remain of constant quality. Datasheets for different particle sizes are available via our Sales Managers. You can easily contact your local LKAB Minerals sales team member to learn more about the use of our product for density separation. Select your country in the below contact field and you will find all relevant contact details.