Applied in plastics and rubbers.

Halogen-free flame-retardant mineral.

Engineered to perform reliably under demanding conditions, UltraCarb supports applications in both construction and manufacturing, meeting the needs of industries where protection against fire hazards is essential.

Certified

UltraCarb is an exceptional flame resistant mineral solution offered by LKAB Minerals. Known for its dual functionality, UltraCarb acts as both a flame retardant and smoke suppressant, making it a vital component for industries focused on safety and compliance. Suitable for use in a range of applications, including polymers, cables, and building materials, UltraCarb is a preferred mineral choice for sectors where high levels of fire resistance are critical.

UltraCarb is a cost-effective mixture of minerals, which is also known as HMH. It is a proven fire-retardant filler, used in a wide range of polymers and rubbers such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), ethylene-propylene diene monomer (EPDM) and nitrile rubber (NBR).

The combination gives a unique product in which specific properties can be optimised by selected mining and processing to fit a variety of applications.

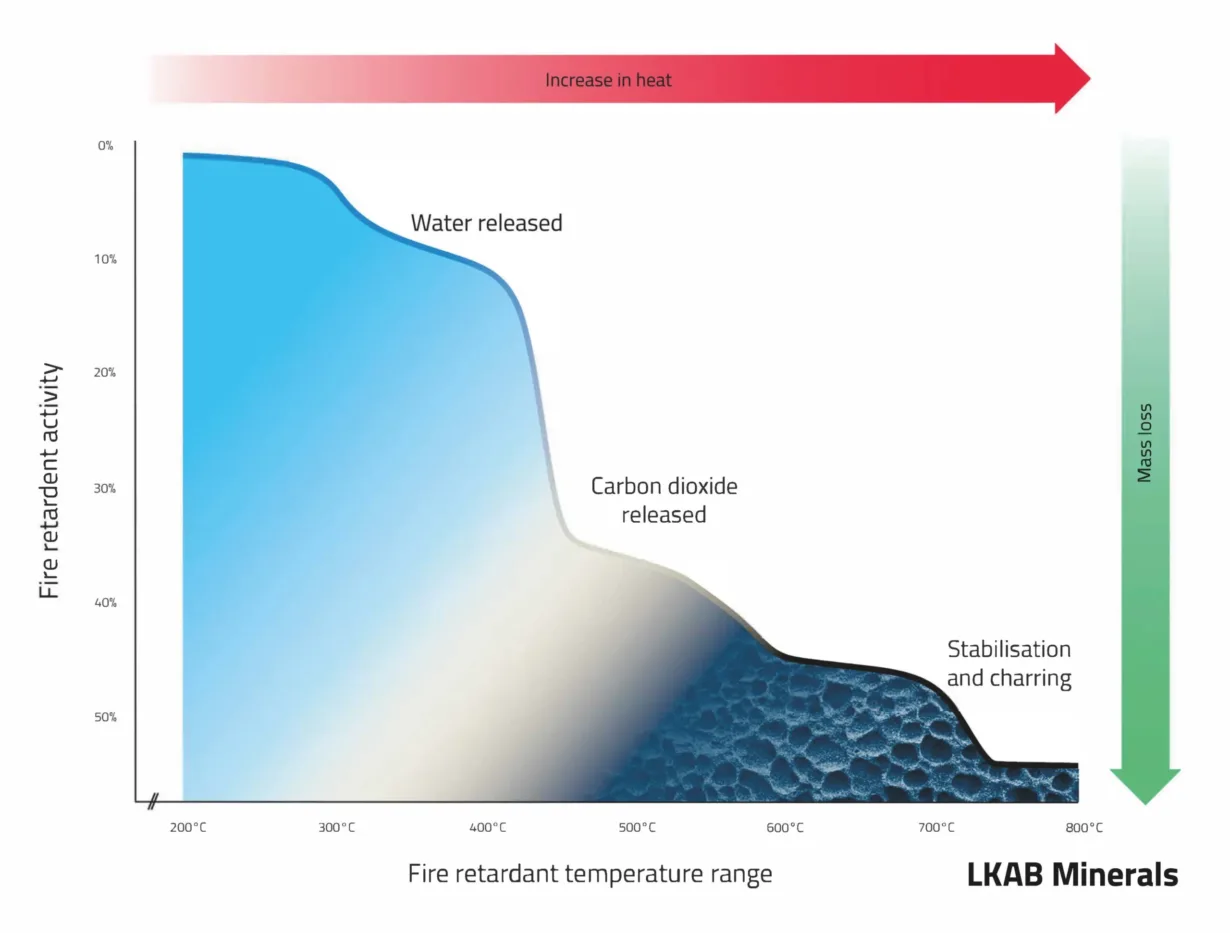

UltraCarb has a unique 3-stage fire-retardant mechanism. Whereas the classical endothermic flame retardant fillers act by releasing water in a single action process, our product works as follows:

The platy, high surface area particles of our halogen-free mineral provide excellent properties when you use these as a functional filler in polymers. The products’ high heat absorption protects polymers from rapid thermal degradation and the formation of combustible products.

| Primary Hydromagnesite | Primary Huntite |

| LH3 | 1250 |

| LH15 | 1251 (stearate surface treated) |

| LH15C (stearate surface treated) | 1253 (proprietary surface treated) |

| LH15X (proprietary surface treated) | 1290 |

| 1291 (proprietary surface treated) |

Our UltraCarb product range is available in 25kg paper bags, 1000kg bulk bags or in bulk within a tanker.

Stearate surface treatment improves wetting and reduces the agglomeration in the compound. Proprietary surface treatments are beneficial as an external lubricant, act as a processing aid for extrusion and improve the LOI in EVA.

UltraCarb is a natural mineral composed of huntite and hydromagnesite, primarily used as a halogen-free flame retardant and smoke suppressant in various industries. Some key applications include:

Plastics & polymers

Construction & building materials

Coatings & paints

Textiles & fabrics

Wire & cable industry

| Specific gravity [g/cm3] | 2.4 |

| Refractive index | 1.56 |

| Hardness (Mohs) | 2.5 |

| Surface area [m2/g] | 11 – 17 |

| Loose bulk density [kg/l] | 0.4 |

| MgO [%] | 36 – 39 |

| CaO [%] | 6 – 9 |

| SiO2 [%] | 0.2 – 1 |

| Loss on ignition at 1,000°C | 51 – 54 |

The naturally occurring mixtures of Hydromagnesite and Huntite mineral deposits are formed by near surface geochemical processes. The formation of our own Turkish deposits is the result of three specific conditions:

The precipitation of HMH is related to the mixing of ground water with fresh water from the lake environment.

UltraCarb is naturally halogen-free, therefore does not emit toxic smoke when burnt.

UltraCarb from LKAB Minerals offers reliable flame-resistant solutions tailored to your industry’s needs. Contact our team for detailed information and guidance on integrating UltraCarb into your projects!

You can also find us on social media channels such as Facebook, LinkedIn and YouTube. Together, let’s build a better future with high-quality minerals.

If you wish to have your personal data removed after submitting this form please contact us directly. See our privacy policy for contact details.

Terms & Privacy policy