Industrial uses of MinSand

In a wide range of high-performance industrial applications, consistent product quality, temperature stability, and environmental compliance are essential. MinSand, an engineered, synthetic mineral from LKAB Minerals, delivers all three. With its unique physical properties and clean production profile, MinSand has become a valuable mineral in several industrial sectors, particularly foundry applications, ceramics, and refractories.

As industries seek environmentally responsible and durable material solutions, MinSand offers not just a substitute but a step forward. Providing manufacturers with a high-purity, consistent, and environmentally conscious choice.

What is MinSand?

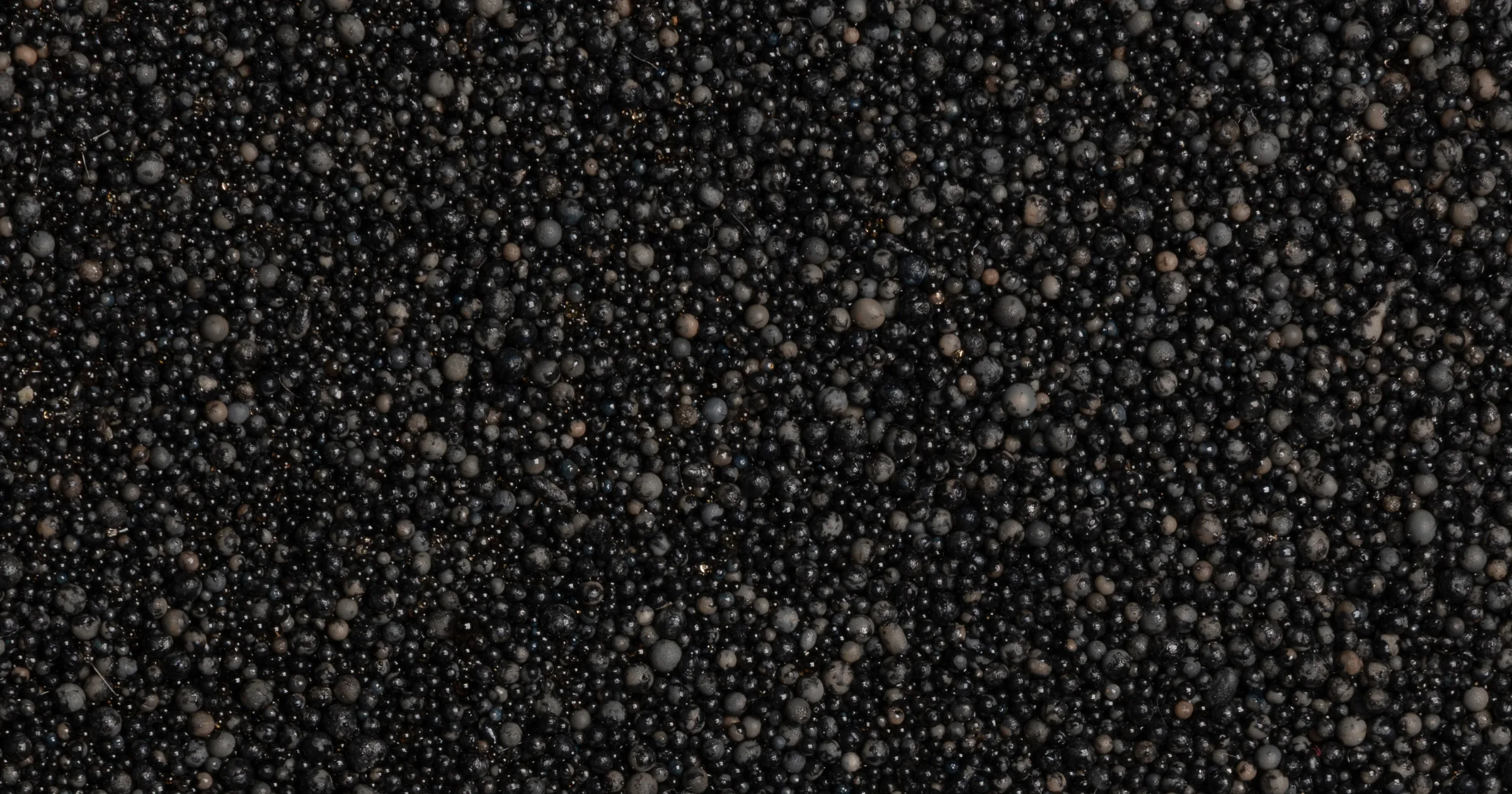

MinSand is a synthetic mineral composed of alumino-silicate and manufactured through a controlled sintering process. The result is a spherical, homogeneous material with a consistent grain shape, high thermal resistance, and excellent flow characteristics.

Unlike natural minerals, MinSand offers predictable performance across batches, giving manufacturers greater control over their end products. It also avoids some of the supply chain, regulatory, and environmental issues associated with traditional alternatives.

Foundry applications

One of the most significant industrial uses of MinSand is in the foundry industry, where it serves as a superior alternative to traditional minerals. In precision casting – especially in automotive and heavy machinery sectors – MinSand provides high-temperature resistance and dimensional stability, which are essential when creating complex metal components.

Its spherical grain shape ensures excellent flowability and compaction, improving mould integrity and reducing the risk of defects such as veining, penetration, or burn-on. These benefits lead to smoother casting surfaces and reduced post-processing costs.

In addition, MinSand is chemically inert and non-reactive, making it suitable for casting both ferrous and non-ferrous metals. Its controlled particle size distribution also helps optimise gas permeability and reduces casting defects, leading to higher yield and lower waste.

Ceramics and refractories

In the ceramics and refractory industries, MinSand is used to manufacture high-performance products exposed to extreme thermal and mechanical stresses. Thanks to its high melting point and thermal shock resistance, MinSand is ideal for creating kiln furniture, insulating bricks, refractory linings, and other heat-intensive components.

In ceramic applications, its consistent grain shape and chemical purity contribute to improved material strength and dimensional stability. This makes MinSand an excellent ingredient in precision ceramic moulds and technical ceramics that require reliable performance under high heat.

For refractory producers, MinSand helps maintain thermal integrity in harsh industrial environments such as steel production, glass manufacturing, and incineration plants. It offers a durable and consistent material base that withstands repeated heating and cooling cycles without degradation.

Environmental and health advantages

Unlike traditional sands, which are often linked to hexavalent chromium (Cr(VI)) contamination and associated health risks, MinSand is free from harmful elements and does not produce hazardous dust. This makes it safer for handling during production, especially in casting environments where air quality and worker safety are a concern.

MinSand’s synthetic nature also enables a more environmentally responsible and traceable supply chain. Manufactured in controlled conditions with minimal impurities, it meets strict environmental regulations and reduces the ecological footprint of industrial operations.

For companies focused on achieving regulatory compliance and improving their ESG (Environmental, Social, and Governance) profile, MinSand provides a proactive solution.

Benefits of using LKAB Minerals’ MinSand

LKAB Minerals is a trusted global supplier of industrial minerals, and our MinSand product exemplifies our commitment to quality, safety, and innovation. Some of the key benefits of using our MinSand include:

- Consistent particle size and shape for reliable moulding and casting.

- High thermal resistance is ideal for high-temperature applications.

- Chemically stable and non-hazardous alternative to chromite.

- Improved flowability and compaction in foundry moulds.

- Environmentally friendly production process.

- Flexible usage across multiple industries, including foundry, ceramics, and refractories.

Our technical teams work closely with customers to ensure MinSand is tailored to their specific application needs. Whether you’re seeking to improve casting quality, reduce health risks, or achieve tighter dimensional tolerances, MinSand offers a proven path forward.

MinSand has earned its reputation as a smart, clean, and consistent alternative to traditional sands in a range of industrial applications. Its performance in high-heat, high-precision environments – combined with its safety and environmental credentials – makes it a go-to material for foundries, ceramic manufacturers, and refractory producers worldwide. To learn more about how MinSand can enhance your industrial processes, visit the MinSand product page or contact our team of experts today. You can follow us on LinkedIn to stay updated with our latest news and developments.