Magnetite for radiation shielding materials: safety in medical & nuclear facilities

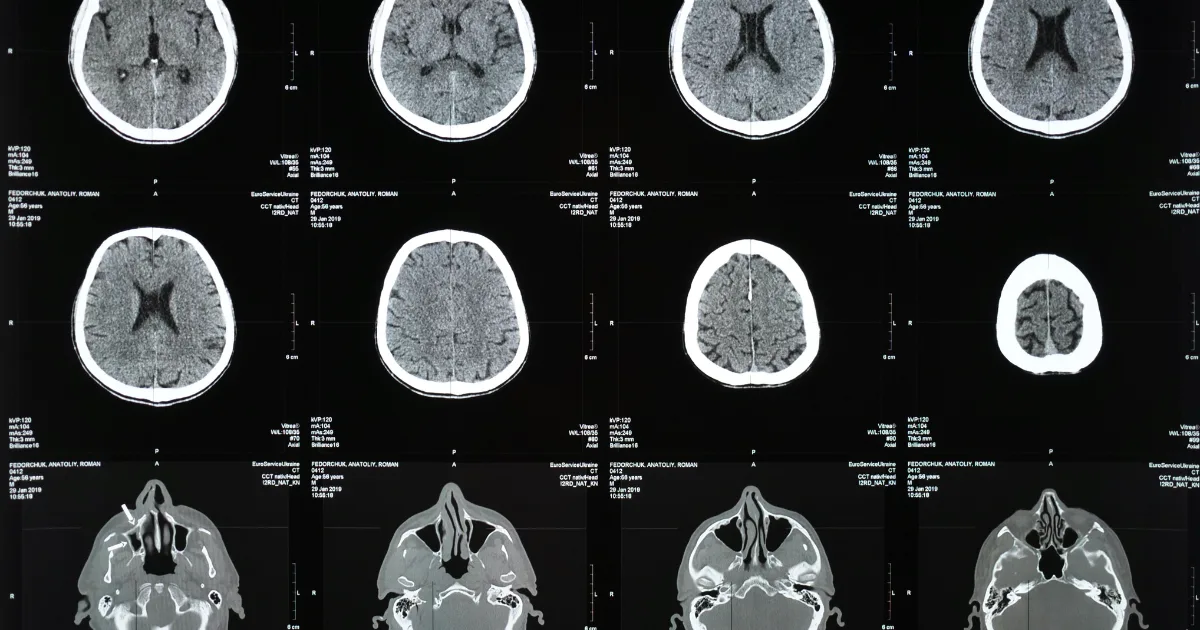

Radiation shielding plays a critical role in ensuring safety in both medical and nuclear environments. From hospitals using X-ray, CT, and radiotherapy equipment to nuclear facilities handling radioactive materials, the protection of workers, patients, and the public depends on high-performing shielding solutions. One mineral that is a popular choice for radiation shielding materials increasingly chosen for these applications is magnetite, used in the form of MagnaDense high-density aggregate.

By incorporating MagnaDense into concrete, engineers can create structures that block or attenuate harmful radiation more effectively than standard concrete, without compromising on constructability or durability. This blog explores how magnetite works as a radiation shield, why it is vital in healthcare and nuclear sectors, and how LKAB Minerals supports safe, efficient projects worldwide.

Why radiation shielding materials matter

In medical and nuclear settings, radiation is a powerful tool, but it comes with risks if not carefully controlled. Ionising radiation, such as gamma rays and neutrons, can cause serious health effects with prolonged exposure. For this reason, radiation shielding is a regulatory requirement in hospitals, research facilities, nuclear power plants, and waste storage sites.

Concrete is already a widely used shielding material thanks to its availability, strength, and cost-effectiveness. However, standard concrete can be bulky when very high protection levels are needed. By increasing concrete’s density with magnetite aggregate, shielding performance improves significantly, allowing walls to be up to 50% thinner while still meeting safety standards. This space-saving benefit is particularly valuable in hospitals, laboratories, and retrofit projects where the footprint is limited.

How MagnaDense delivers effective shielding

MagnaDense from LKAB Minerals is produced from natural magnetite ore and offers a density of up to 5.2 t/m³ in loose form, or over 3.5 t/m³ in concrete, compared to around 2.4 t/m³ for standard concrete. This higher density means radiation has less distance to travel between atoms, greatly reducing its penetration.

Used worldwide in both medical and nuclear shielding projects, MagnaDense concrete is:

- Proven in performance – tested and applied in gamma and neutron shielding.

- Compatible with standard equipment – no special mixing or placing equipment required.

- Versatile – suitable for in-situ casting or precast blocks, walls, and panels.

- Durable – provides long-term stability without degradation under radiation exposure.

Applications in medical facilities

Hospitals, cancer treatment centres, and diagnostic imaging suites rely on high-performance shielding to protect staff and patients. Common uses for MagnaDense in healthcare include:

- Radiotherapy bunkers – ensuring safe delivery of high-energy treatments.

- X-ray and CT scan rooms – preventing leakage into adjacent spaces.

- Proton therapy facilities – shielding against both gamma and neutron radiation.

The reduced wall thickness achievable with MagnaDense concrete can help optimise room layouts, speed up construction, and reduce material costs while maintaining patient safety.

Applications in nuclear facilities

In nuclear power generation, decommissioning, and waste storage, shielding is critical for worker protection and environmental safety. MagnaDense concrete is widely used for:

- Reactor shielding structures – containing radiation during operation and maintenance.

- Spent fuel storage – providing long-term protection for radioactive waste.

- Containment walls – ensuring safe operation of nuclear research laboratories.

Its durability and high density make MagnaDense a dependable choice for these safety-critical applications.

Best practice for specifying magnetite shielding

Early engagement between engineers, radiation physicists, and suppliers like LKAB Minerals is key to achieving optimal results. Factors such as density targets, wall thickness, and radiation type should be discussed during the design phase. LKAB Minerals offers technical advice, supply chain reliability, and proven case studies to guide your project.

Whether poured in-situ or used in precast elements, MagnaDense concrete is as straightforward to produce and place as standard mixes, ensuring no compromise on buildability.

Proven expertise, global supply

With decades of experience in supplying magnetite for shielding projects worldwide, LKAB Minerals has supported installations from hospital treatment rooms to large-scale nuclear sites. Our technical team works closely with designers and contractors to ensure that every project meets regulatory requirements while optimising space and cost.

If your project requires high-performance radiation shielding, our experts can help you specify and source the right grade of MagnaDense. Get in touch today for tailored advice, density calculations, and availability. You can also explore our MagnaDense product page for more technical information and case studies, or follow us on LinkedIn for the latest updates, case studies, and product releases!