The role of Andricite in high-performance floor screeds

In construction, floor screeds form the foundation for every internal floor finish, supporting everything from residential floorboards to heavy-duty commercial tiling. The demand for faster, stronger, and more dimensionally stable screeds has led to innovations in binder technology and Andricite is at the forefront of this evolution.

Engineered by LKAB Minerals, Andricite is a high-purity synthetic anhydrite binder developed for flowing floor screeds. It provides a modern alternative to traditional cement-based systems, combining workability, strength, and environmental responsibility in one consistent material.

Whether you’re working on large-scale housing, high-spec commercial developments or time-sensitive refurbishments, Andricite-based screeds can deliver a smoother finish, quicker drying time, and improved long-term performance.

What is Andricite?

Andricite is a synthetic anhydrite – a calcium sulphate-based binder – specially manufactured to tight specifications. Unlike natural gypsum or cement binders, Andricite offers highly consistent physical and chemical properties. It is used as the core binder in calcium sulphate flowing screeds (also known as self-levelling or liquid screeds).

Sourced and refined by LKAB Minerals, Andricite is designed to be mixed with selected aggregates, water, and additives to produce screeds that outperform traditional solutions across multiple construction environments.

Why choose Andricite-based screeds?

Andricite delivers a series of key technical and practical benefits, making it a trusted choice for screed manufacturers, flooring contractors, and developers.

1. Excellent flow and placement

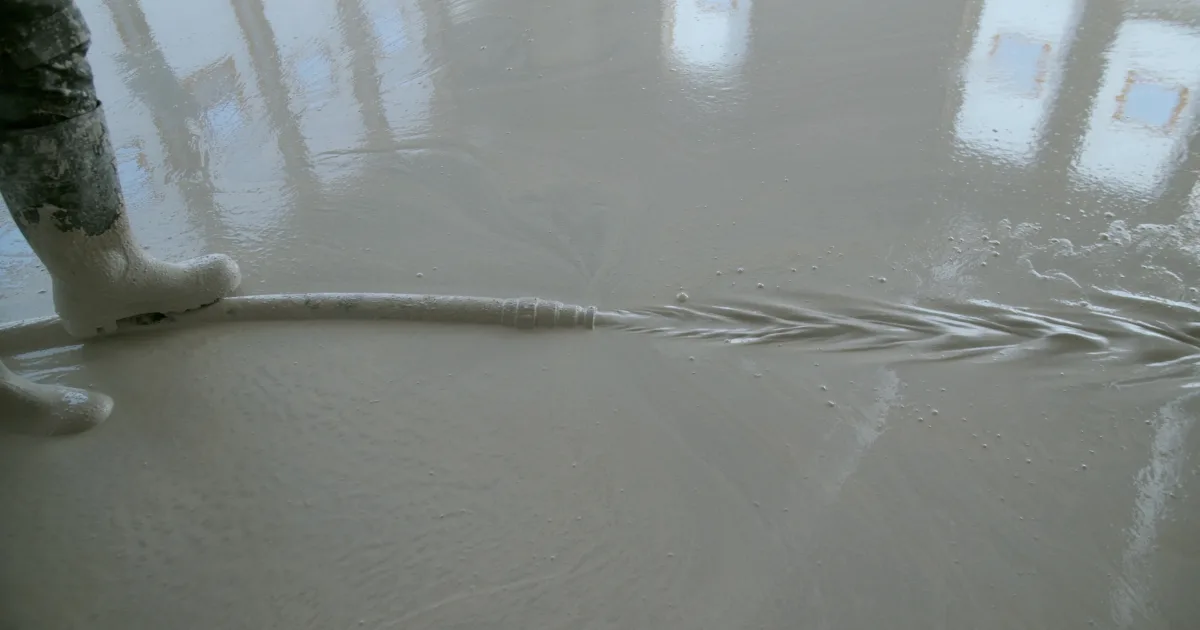

One of the standout qualities of Andricite screeds is their fluid consistency. The high flowability of the mix enables quick, uniform installation, especially useful for large surface areas, intricate layouts, or installations with underfloor heating.

This self-levelling behaviour reduces the need for manual compaction or finishing, cutting down on labour time and minimising the risk of voids or imperfections.

2. Reliable drying times and early strength

Andricite’s reactivity is carefully controlled, which helps achieve predictable drying and strength development. Unlike cement-based screeds, which can vary depending on site conditions and mix inconsistencies, Andricite screeds typically offer faster strength gain and earlier foot traffic readiness.

This makes them ideal for fast-track projects, such as schools, office refurbishments, and retail fitouts, where construction schedules are tight and floor coverings need to be installed as soon as possible.

3. Dimensional stability and reduced cracking

Thanks to the low-shrinkage nature of calcium sulphate binders, Andricite screeds exhibit excellent dimensional stability. This means less curling, fewer shrinkage cracks, and minimal movement during curing. In most cases, no movement joints are needed within floor areas up to 1000 m² – a major advantage over cement screeds that often require multiple expansion joints.

This stability also ensures compatibility with thin floor coverings, improving final floor performance and reducing maintenance costs in the long term.

4. High thermal conductivity for UFH systems

Andricite screeds have become the go-to choice for underfloor heating (UFH) applications. Their dense, low-void matrix enables better heat transfer, faster warm-up times, and more consistent floor temperatures.

The material fully encapsulates heating pipes and delivers excellent thermal conductivity, helping reduce energy costs and improving comfort in residential and commercial environments alike.

5. Lower environmental impact

With growing emphasis on reducing carbon emissions in construction, Andricite offers a more environmentally responsible solution. Unlike traditional Portland cement, which involves high CO₂ emissions during production, Andricite’s calcium sulphate base requires significantly less energy to process.

It also supports circular economy goals, as some sources of synthetic anhydrite are derived from industrial by-products, giving new life to otherwise unused materials.

Common applications of Andricite screeds

The versatility of Andricite-based screeds makes them suitable for a wide range of projects, including:

- Residential housing – For smooth, level finishes and effective underfloor heating integration.

- Commercial properties – Offices, showrooms, and retail spaces benefit from faster drying and high durability.

- Healthcare and education – Screeds with minimal cracking and low dust emission are ideal for hygiene-sensitive environments.

- Industrial and logistics – Where dimensional stability and strength are key, Andricite screeds provide reliable performance for light to medium-duty use.

The ease of application and ability to cover large areas without joints also make them a top choice for modern construction projects prioritising speed, precision, and floor quality.

How LKAB Minerals supports screed performance

As the supplier of Andricite, LKAB Minerals works directly with screed manufacturers and contractors to ensure performance and compliance at every stage of production and application.

Our services include:

- Consistent supply of Andricite in bulk or bagged form

- Technical guidance on formulation and screed design

- Compliance support with EN 13813 and other relevant standards

- Advice on drying times, surface preparation, and floor coverings

- Training for mixing and installation best practices

Our technical teams are always available to help you optimise Andricite screed mixes for your specific project or product range.

A smarter approach to modern screeds

Andricite is more than just a binder – it’s a high-performance material that reflects the changing needs of the construction industry. From improved productivity and aesthetics to greater environmental responsibility, Andricite is engineered to meet both commercial and technical demands in a single solution.

If you’re a screed manufacturer looking to refine your formulations or a contractor seeking reliable performance on site, Andricite offers a competitive advantage. Visit our Andricite product page to learn more or contact our team for expert advice and tailored support. You can also follow LKAB Minerals on LinkedIn to stay up to date with the latest product developments, case studies, and industry insights.