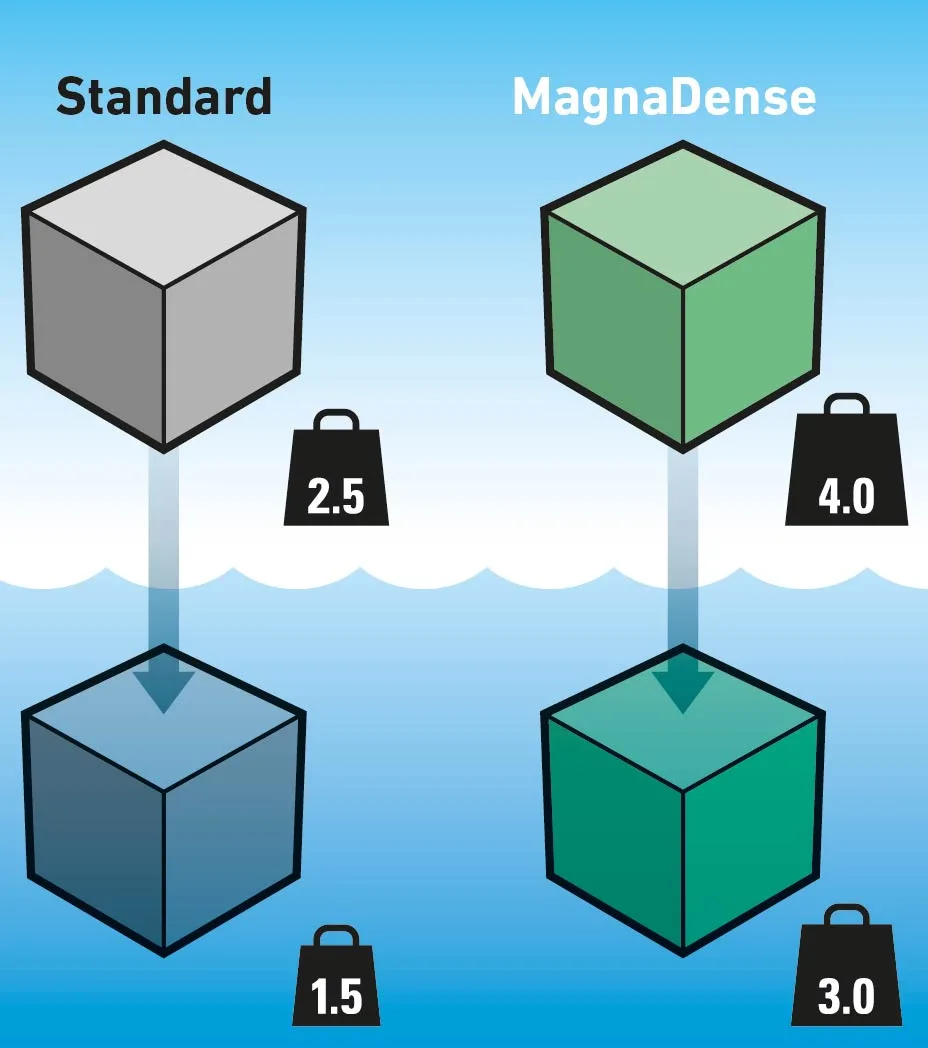

MagnaDense is a high density aggregate, used as heavy weight ballast in many applications; either as a loose ballast aggregate or incorporated into concrete.

Whether your need is for heavy weight to balance a bridge, to keep a gravity-based structure in place, to make a counterweight for heavy vehicles or any other ballast project, you’ll need a high density material to get the right weight for your design.

Depending upon your application MagnaDense can be used as a loose ballast or concrete ballast with high density. The main reason for choosing our product is because of its weight, but there are many additional reasons to opt for the LKAB Minerals heavy aggregate. We have listed the important benefits of our natural high density material below:

Which benefit is most important for you as a ballasting company and your project in particular? Tell us in a one-on-one conversation with a regional sales manager who can help you select the right grades, getting the right ballast density. Contact details can be found on this page.

LKAB Minerals has supplied MagnaDense ballast for concrete or as loose ballast to many projects all over the world such as offshore foundation ballast and marine ballast weights. For some projects, you can find more information on this website. Please click on the links below and take a look at the following detailed projects:

For some of the ballasting projects we have been involved in, we have created detailed documents which are available upon request:

Of course, we have supplied our heavy aggregate for many other projects which we can tell you about in person.

We manufacture MagnaDensefrom the natural mineral Magnetite and mine this from our resources in Kiruna, Northern Sweden. It has a natural density of up to 5.1 t/m3. The product is harmless to the environment and non-toxic in all its forms.

Contact us for datasheets, product definitions and case studies or for help to select the best density for ballast using MagnaDense for your project. We look forward to making your next ballasting project a perfectly balanced one!